Upgrade kit from WorkBee Screw Driven CNC to QueenBee ULTRA CNC

Upgraded kit from Workbee Screw Driven to QueenBee ULTRA CNC MachineQueenbee

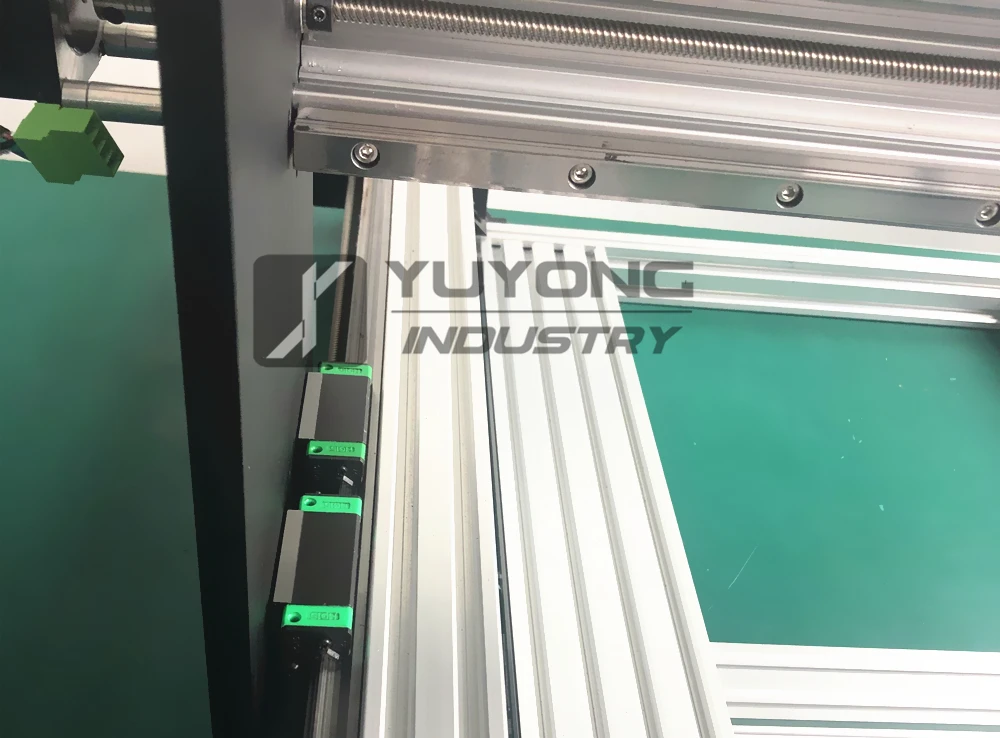

The YUYONG INDUSTRY QueenBee ULTRA is a super Performance Improvement version,High-rigd and High-Precision CNC machine with Full Track Linear Rail Upgrade based on very well-received WorkBee CNC machines.

Its many super upgrades have greatly improved the mechanical performance of the entire machine in terms of frame design or rigidity and precision.

With Full Series size,no matter Cutting or 3D carve wood,pcb plastics, aluminum, etc. to create beautiful intricate 3D carvings, inlays, furniture, signs, plaques, amazing works of art and so much more. All can be achieved here!

There are 3 Options:

-

WB V1 to QB ULTRA

-

WB V2 to QB ULTRA

-

WB V2.3 to QB ULTRA

Note:

-

The YUYONG INDUSTRY QUEENBEE is Universal and Interchangeable.Any WorkBee Machines can be upgraded,not only YUYONG INDUSTRY WorkBee Machines.

-

The YUYONG INDUSTRY QUEENBEE Machine has passed QA and QC after many tests.All are Real Product Photos.

-

If you need Black Extrusion Version,please contact us to get the price difference.

-

If your machine is Belt Driven,please contact us to get the conversion kit.

Not Sure Which one to Buy?

WorkBee V1.0

Your WorkBee hasno Lengthened Lead Screw and Lead Screw Tensioner and New Tensioning system, you need to buyWB V1 to QB ULTRA.

WorkBee V2.0

Your WorkBee hasLengthened Lead Screw and Lead Screw Tensioner,but no New Tensioning system, you need to buyWB V2 to QB ULTRA.

WorkBee V2.2

Your WorkBee hasLengthened Lead Screw and Lead Screw Tensioner and standard Tensioning system,but no Tension nut,you need to buyWB V2.2 to QB ULTRA.

Original Name of QueenBee

The Original QueenBee is designed by CNC 3D,which located in Queensland, one year ago,David Nestor of CNC 3D introduced us to this QueenBee and other their machines when order from us.

The Original QueenBee is also great work,with X Y Z thickened gantry plate to increase Strength and overall rigidity,use the precise Linear Rail Guide System to Replace rolling Wheels.But There may some limitmations on Lead Screw Assembly and Frame rebuilding of WorkBee, and also redesigning of X Y Z Gantry Plates and End plates. These Enhanced upgrades to make sure the CNC machine become a very power CNC machine. So We rename it “QueenBee Ultra”!

Why need to Upgrade?

The WorkBee is a popular and well-designed CNC machine, it use V Wheel system to assembly X Y Z Axis to roll,If you have ever assembled a machine, you will know how frustrating it is to adjust the wheel to the same force balance.And Also,the wheel system only bear one direction force.When you put heavy spindle on Z Axis or Load on X Axis,the Wheels are not enough to support the weight,uneven force caused flex of X And Z Axis long term.

YUYONG INDUSTRY is committed to overcoming shortcomings and providing integrated solutions,Taller and thickened Plates with upgraded Linear Rails increased rigidity of the linear rails to make the machine more stable,at same time reduce the flex of X And Z axis,this allow the machine to support more heavier parts and bigger size.

On the other hand,the QueenBee ULTRA make a smooth and precise surface when milling soft metals such as aluminum or other materials via it’s stability,greatly reduce the hedging during V Wheel Working.This provides more possibilities for increasing speed and high feed.

So there may a necessary to upgrade your machine.

Why Choose Linear Rail Guide?

There are many upgrade system can be used on CNC machines, such as Rod Linear Motion,Gear System,Linear Rail Guide system and other system.But after many testing and comparing,Linear Rail Guides are considered to be the most comprehensive system with its own structural characteristics.

Linear guides are generally used in linear reciprocating motion applications, and have higher load characteristics than linear bearings, bear a certain torque coefficient, and can achieve high-precision linear motion under high load conditions.

It is a kind of rolling guide, in which the steel ball rolls infinitely between the slider and the guide rail, so that the load platform can easily move along the guide rail with high precision and linear motion, and the friction coefficient is reduced to 50% of the usual traditional sliding guide, can easily achieve high positioning accuracy. The design of the terminal unit between the slider and the guide rail makes the linear guide rail bear the load in all directions, such as up, down, left, and right at the same time. The patented recirculation system and simplified structural design make the linear guide more smooth and low-noise movement.

Advantage:

-

Low noise during high-speed operation

-

New guide rail wear resistance

-

High precision and easy to disassemble

-

Simple assembly and universal accessories

-

Low cost and good efficiency

Its excellent characteristics have been widely used on industry, medical, science, defence, mining, construction, transportation.

Queenbee ULTRA Upgrade Features

-

High Precision CNC processing Deluxe Thickened QueenBee Plates

-

Integrated dedicated Nut Block Spacer

-

High precision Ultra Mute Linear Rail System

-

Brand New Lead Screw Locking Tensioning System

-

Convenient Jog Knob for Y and A Axis.

-

New Designed Extended Y End Plates to match the Nut blocks and Lead Screw in order to increase the rigidity of Y Axis.

-

The back support which firmly attached to X Axis using the black corner connectors,can prevent Flex farthest and increase the rigidity,as well as burden more heavy parts.

-

Thickened Y Plates with Dual Linear Sliders to reduce any change of twist on Axis.

-

All-New Reinforced “Cross” Frame to make the base stable and strengthening.

-

Further Strength and consolidate the stability of bottom frame.

-

High strength Slide T nuts to replace Drop In T nuts,make the Linear rail fixed on Aluminum Extrusion better.

P.S: